Floor Coating

PROTECH NH-270(LP) Hybrid polyurea

- usage

- Waterproof flooring material for various engineering works and buildings, flooring material for steel structures, water tank waterproofing and coating for maintaining cleanliness

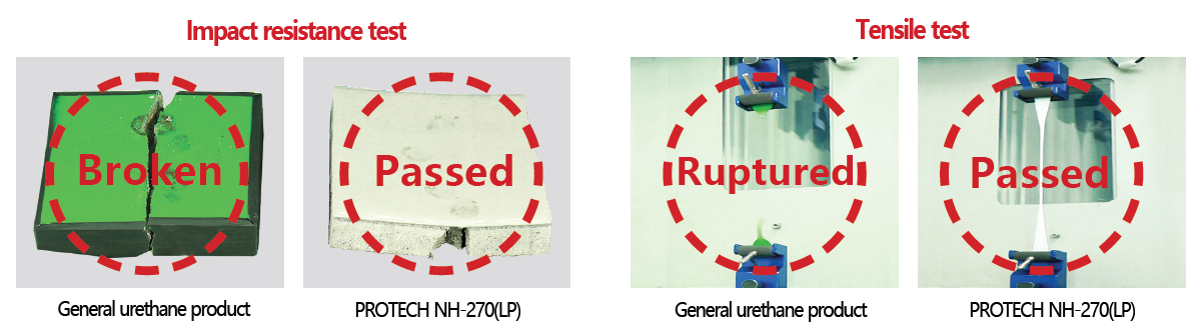

PROTECH NH-270(LP) is a paint applied using a dedicated spray equipment. The product is a special paint mainly composed of the bonding between urea and urethane with its fast curing reaction resulting in a coating (film). The coating is a hybrid-type urea paint with excellent elasticity, abrasion resistance, and elongation, and extremely excellent impact resistance, cold resistance, water resistance, durability, and adhesion.

specification

- Paint type

- Polyurea / Intermediate coating (Two-Component)

- Drying time

-

Drying time Category 5℃ 20℃ 30℃ Set-to-touch Within 1 minute Within 1 minute Within 1 minute Dry-through Within 2 hours Within 1 hour Within 1 hour - Thinner

- Not applicable

- Dilution ratio

- -

- Specific gravity

- Approx. 1.05 (Mixed)

- Theoretical Coverage

- 2.2 ㎏/㎡ (Based on 2㎜)

- Solid volume ratio

- 99%

- Color

- Green, gray, other ordered colors

- Mixing ratio

- Base(A)/hardener(B)=100/100 (Volume ratio)

- Shelf life

- 6 months (5~35℃ indoor storage)

- Packaging unit

- 30.8 ㎏ [Base(16 ㎏), Hardener(14.8 ㎏)]

PRODUCT PROPERTIES (PHYSICAL PROPERTY DATA)

- Tensile strength

- More than 10 N/㎟

- Tearing strength

- More than 35 N/㎜

- Elongation rate

- More than 450 %

- Hardness

- shore A 70 ± 5

how to use

- Surface treatment

- 1. Completely remove oil, moisture, sand, dust, and other foreign matter from the surface to be coated.

2. Cure concrete for at least 28 days at a temperature of 21℃ and a relative humidity of 60%.

3. Remove the protruded parts using a grinder. Cracks on the surface should be repaired before coating. - Coating method

- 1. Apply by using exclusive spraying equipment within one day after primer.

2. Use the hardener containing pigments after sufficiently stirring with a drum stirrer before use.

3. For a base made of steel, apply after blasting surface treatment and primer treatment.

4. If the surface condition is poor after primary coating, reapply within 24 hours.

5. Upon spray coating once back and forth, a coating thickness of 0.2~0.3㎜ can be obtained, and the coating

thickness desired for continuous work can be formed.

Recommended construction equipment: SPRAY equipment for polyurea (Graco/Gusmer Reactor E-XP 2 or higher)

▷Primer : PROTECH 100 (or CLEANTHANE 1000, BLACKTHANE 100) (It may vary depending on the substrate)

▷Intermediate coating: CLEANTHANE 2100(KSF-3211) can be used as a base adjusting agent.

▷Top coat : PROTECH 300 (or DHDC-3000(H)) (coating for external exposure) - Coating conditions

- 1. If the temperature of the substrate is -5~50℃, spraying is possible.

2. Moisture content in the concrete: 6% or less