Architecture Paint

SOON&SOO ALL COVER

- usage

- Concrete, cement mortar, plasterboard, steel, non-ferrous metal, wood, wallpaper etc.

Interior/exterior wood, enamel/lacquer old coating repairs

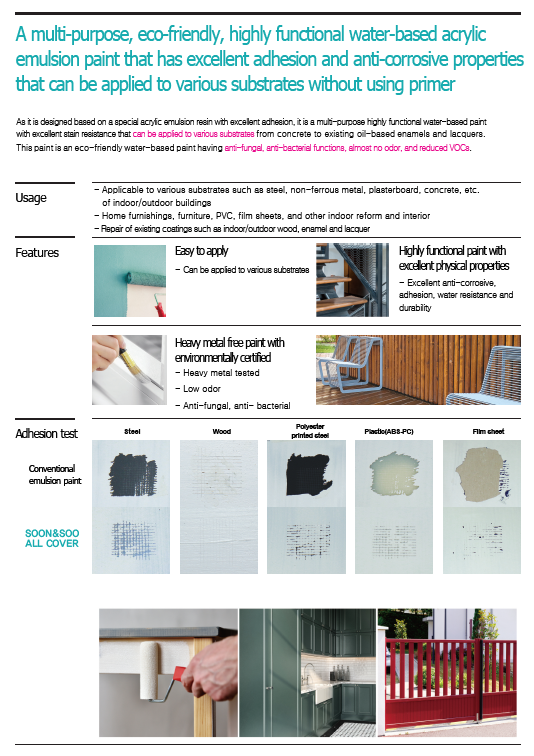

Soon & Soo All Cover is a multi-purpose water-based paint that can be applied to a variety of substrates, including concrete, steel, and existing old coatings by applying a special emulsion resin with excellent adhesion. This paint is an eco-friendly water-based paint that has excellent antibacterial/anti-fungal properties and dramatically reduces VOC (volatile organic compounds), and comes in a variety of glosses from matte to glossy.

specification

- Paint type

- Special acrylic emulsion water-based interior, exterior / Top coat

- Drying time

-

Drying time Category 5℃ 20℃ 30℃ Dry-hard 3 hours Time required for re-coating (min.) 3 hours - Thinner

- Tap water(dilution rate: up to 10%, volume ratio)

- Coating Method

- Brush, roller, spray coating

- Specific gravity

- Approx. 1.31(based on glossy white color)

- Solid volume ratio

- Approx. 42%(based on white color)

- Theoretical Coverage

- 14.0 ㎡/ℓ/1time

- Thickness of dried film

- 30㎛ (1coat recommended)

- Re-coating interval

- 20℃, sufficient ventilation for a minimum of 3 hours

- Color

- White, other colors

- Gloss

- Glossy / Semi-gloss / Eggshell / Matte

- Storage and preservation

- 12 months (Dry, cool, and dark place with good ventilation, room temperature 5℃~30℃, humidity less than 80%)

how to use

- How to use

- 1. New painting - interior and exterior finishing of buildings such as concrete, cement mortar, wallpaper, gypsum board, and steel (for light duty)

2. Repair painting - Repair of old paint films such as water-based old film, acrylic, enamel, lacquer, etc.

(Adhesion failure may occur under two-component urethane, epoxy, heat curing, and UV curing old film conditions)

* Wallpaper: When painting silk wallpaper or foam wallpaper, be sure to use a matte product.

* Steel: For light duty use, heavy duty material requires anti-rust paint to prevent corrosion over a long period of time.

* Enamel, lacquer: As time passes, the old film becomes harder, so be sure to sandpaper and then paint to improve adhesion.

* When painting non-ferrous metals and oil-based old films, it is necessary to check in advance for adhesion abnormalities.

* Not suitable for floor painting. - Surface treatment

- 1. If there are dust, oil, scribbles in crayons, colored pencils, etc. and dirty finger marks, they should be removed with a neutral detergent diluent the surface should be wiped.

2. Areas infested with mold should be cleaned with a damp cloth after removing the mold using bleach or a mold cleaner. The paint should be applied after completely drying the surface. Be sure to check the detailed painting specifications recommended depending on the type of material you wish to paint before proceeding.

1) Concrete and mortar surface

- The material should be sufficiently cured (cured more than 30 days at 20℃)

- Laitance, dust, oil and other contaminants on the surface must be completely removed.

- The proper pH of the material must be less than 9, and the percentage of moisture content must be less than 6%.

- If the concrete is in poor condition (absorption, cement dissolution, etc.), dilute water-based sealer DNX-4001 and apply with a roller or brush if necessary to prevent poor adhesion and discoloration.

2) New steel plate

- Completely remove any oil contamination remaining on the steel before painting.

(If oil remains, appearance deterioration occurs due to cratering or deterioration of wetting)

- Excellent adhesion is achieved only after uniform sandpaper pretreatment. (SSPC SP-2)

- Before painting, solvent cleaning must be performed and oil must be completely removed.

- Rusted steel must be completely removed using a wire brush, etc. If rust remains, the rust may rise on the coating film.

3) New wood

- Completely remove dust and oil, and sand if necessary.

- Wood exposed to the external environment continuously shrinks and expands depending on moisture, which reduces the durability of the coating film.

4) Repair coating

① Water-based old film

- If the old film is normal, clean the surface of the film, completely remove the old film that is damaged or in poor condition, and then apply water-based sealer DNX-4001 first and then apply subsequent coats.

- For areas with high absorbency, apply one additional coat and dry for at least 3 hours at 20℃.

- Cut the cracked area in a V shape and fill it with putty.

② Alkyd (enamel, combination) old coat

- Completely remove dust, oil, etc., and poorly adhered or damaged paint films with a wire brush or scraper.

- Alkyd paints such as enamel become very hard over time, so be sure to sand the old film with sandpaper to improve adhesion.

- After testing the pre-painting and checking for adhesion problems, if there are no problems apply subsequent paint.

③ If it is difficult to confirm the type of old film, be sure to conduct a pre-coating suitability test to determine it.

④ Wood

- The longer wood is exposed to the outside, the longer it continues to shrink and expand due to moisture, thus reducing the durability of the coating film.

⑤ Wallpaper

- Only matte products are recommended for coated wallpaper such as silk wallpaper or foam wallpaper.

(For coated wallpaper, the plasticizer contained in the coating may rise above the coated surface due to the osmotic pressure balance phenomenon, causing stickiness.) - Coating method

- ① When painting with a thin film (30-40㎛), physical properties such as water resistance and rust prevention may be reduced. Apply this paint twice to get a dry film thickness of 60㎛ with a brush, roller or spray.

② At this time, apply by diluting with water up to 10%.

Do not apply thick coating at once, but divide into two thin coats (In case of lack of hiding power, please apply additional coating.)

③ After 2 coats, the re-coating interval is at least 3 hours after the first top coating at 20℃. - Remarks

- 1. When painting coated wallpaper containing plasticizers, contamination or discoloration may occur due to stickiness.

2. Drying defects may occur during painting due to excessive film thickness.

3. Be careful not to allow leather sofas, wooden furniture, buffers, etc. to come into contact with the wall for a long period of time, as areas that are in contact for a long period of time may experience peeling or contamination of the paint.