Architecture Paint

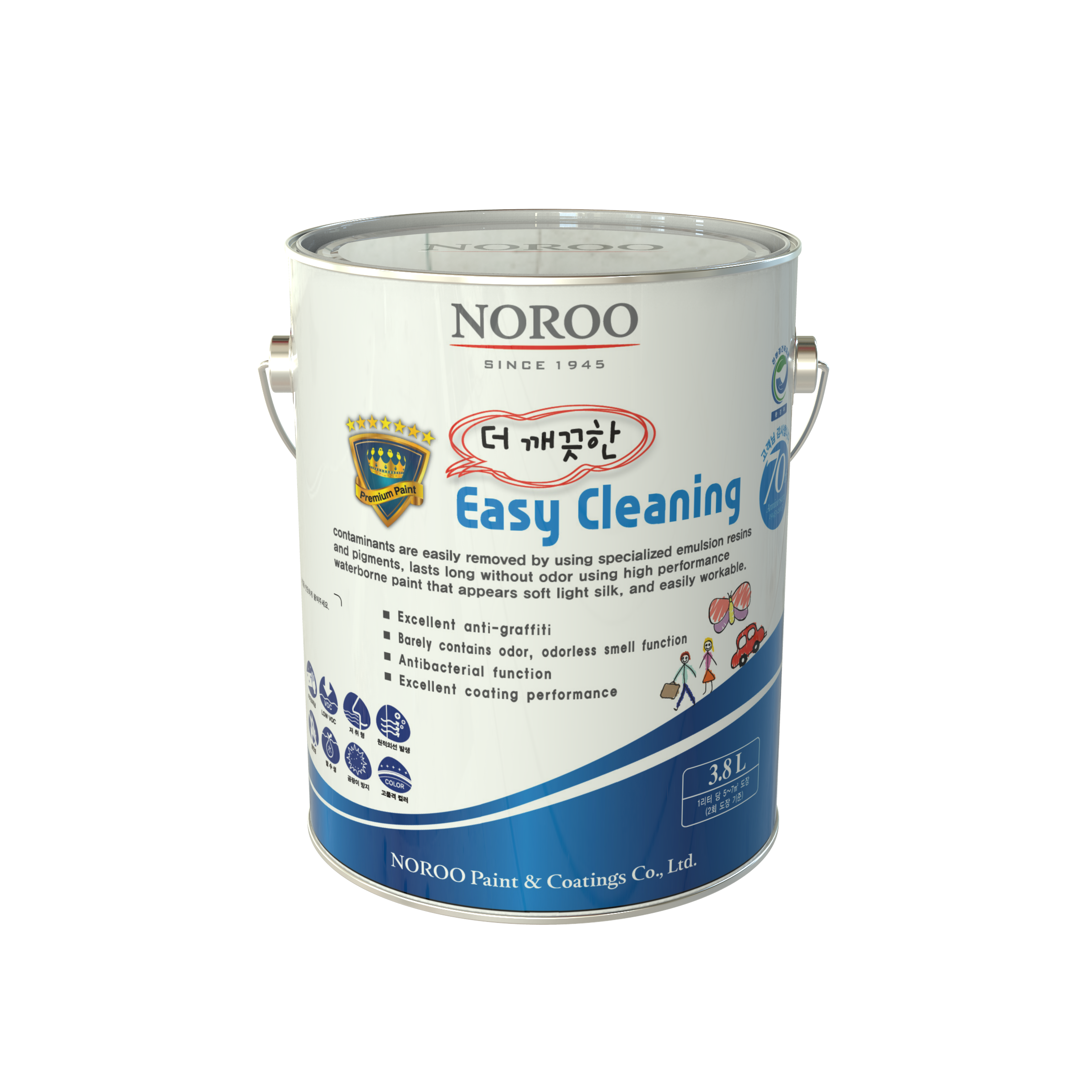

EASY CLEANING

- usage

- Finish coating for interior such as concrete, cement mortar, plasterboard, etc.

As this paint is designed based on a special emulsion resin having a dense structure and pigment, it is easy to remove pollutants. Moreover, it is a highly functional interior water-based paint with the excellent appearance of having a soft egg-shell luster. It also contains antimicrobial agents and has excellent antimicrobial effects. EASY CLEANING not only has no smell of solvent, but also has a good hiding and coating appearance, and can be easily handled by anyone.

specification

- Paint type

- Acrylic emulsion water-based interior / Top coat

- Drying time

-

Drying time Category 5℃ 20℃ 30℃ Dry-hard 3 hours 2 hours 1 hour Time required for re-coating (min.) 6 hours 3 hours 2 hours - Thinner

- Tap water(dilution rate: up to 10%, volume ratio)

- Coating Method

- Brush, roller, spray coating

- Specific gravity

- Approx. 1.3(based on white color)

- Solid volume ratio

- Approx. 35%(based on white color)

- Theoretical Coverage

- 5.8㎡/ℓ/2times

- Thickness of dried film

- 60㎛ (2coats recommended)

- Re-coating interval

- 20℃, sufficient ventilation for a minimum of 4 hours

- Color

- White, other colors

- Gloss

- Egg-Shell

- Storage and preservation

- 12 months (Dry, cool, and dark place with good ventilation, room temperature 5℃~30℃, humidity less than 80%)

PRODUCT PROPERTIES (PHYSICAL PROPERTY DATA)

- Delicate appearance

- Delicate appearance with egg-shell luster.

- Excellent film property

- Due to the dense film composition, stain resistance and graffiti prevention and removal functions are excellent.

- Eco-friendly properties

- It is a LOW VOC, harmful heavy metal FREE and APEO (kind of environmental hormone) FREE eco-friendly water-based paint with little odor during painting.

how to use

- Surface treatment

- 1. The material should be sufficiently cured (cured more than 30 days at 20℃)

2. Laitance, dust, oil and other contaminants on the surface must be completely removed.

3. The proper pH of the material must be less than 9, and the percentage of moisture content must be less than 6%.

4. The gaps and grooves on the surface must be filled with exterior water-based putty, and surface adjustment should be made before coating. - Coating method

- 1. Primer

① After surface treatment, if necessary to prevent poor adhesion and discoloration if the condition of the concrete and the old coating are poor (absorption difference, cement elution, peeling of the old coating, etc.), dilute water-based permeable sealer DNX-4001 and apply once with a roller or brush to a dry film thickness of about 15㎛.

② For areas where the absorption of the surface is severe, apply once more.

2. Top coat

① After at least 3 hour at 20℃ after primer, apply top coat to get a dry film thickness of 60㎛ with a brush, roller or spray twice.

② At this time, if necessary, apply by diluting with water to less than 10% for the one coat and less than 5% for the two coat.

③ After 2 coats, the re-coating interval is at least 3 hours after the first top coating at 20℃.